Ha ho tluoa tabeng ea ho eketsa bokhoni le nako e telele ea litsamaiso tsa hau tsa mechini, khetho ea li-sprocket tsa ketane ke ea bohlokoa haholo. A re qoeleng likarolong tsa bohlokoa tsa thepa, litekanyo, meaho le tlhokomelo tse tla phahamisa ts'ebetso ea hau ho ea boemong bo bocha.

Khetho ea Lintho: Ha ho tluoa tabeng ea ho ntlafatsa litsamaiso tsa hau tsa mechini, khetho ea thepa ea li-sprocket tsa ketane e bohlokoa. U batla ho netefatsa hore meno a li-sprocket tsa hau a na le matla a lekaneng a mokhathala oa ho kopana le ho hanyetsa ho tsofala. Ke ka lebaka leo tšepe ea carbon ea boleng bo holimo, joalo ka tšepe ea 45, hangata e leng khetho e lokelang ho etsoa. Bakeng sa lits'ebetso tseo tsa bohlokoa, nahana ka ho ntlafatsa ho ea ho litšepe tsa alloy tse kang 40Cr kapa 35SiMn bakeng sa ts'ebetso e ntlafalitsoeng.

Meno a mangata a li-sprocket a phekoloa ka mocheso ho fihlela boima ba bokaholimo ba 40 ho isa ho 60 HRC, ho netefatsa hore a ka mamella mathata a ts'ebetso. Ho bohlokoa ho hlokomela hore li-sprocket tse nyane lia kopana khafetsa ho feta tse ling tse kholo 'me li tobana le litlamorao tse kholo. Ka hona, thepa e sebelisoang bakeng sa li-sprocket tse nyane e lokela ho ba betere ho feta tse sebelisoang bakeng sa tse kholo.

Bakeng sa di-sprocket tse hlokang ho mamella moroalo o boima, tshepe e nang le khabone e tlase ke kgetho e ntle haholo. Ka lehlakoreng le leng, tshepe e entsweng ka foreimi e loketse di-sprocket tse nang le tshenyeho empa di sa tobane le ho thothomela ho matla. Haeba tshebediso ya hao e hloka matla a hodimo le ho hanyetsa ho tsofala, tshepe e entsweng ka alloy ke yona tsela e molemo.

Ho tsetela thepa e nepahetseng bakeng sa li-sprocket tsa hau tsa ketane ha ho ntlafatse nako ea tsona feela empa hape ho eketsa katleho ea litsamaiso tsa hau tsa mechini. U se ke ua nyenyefatsa boleng—khetha ka bohlale 'me u shebelle ts'ebetso ea hau e phahama!

Litekanyo tsa Bohlokoa le Likhetho tsa Sebopeho

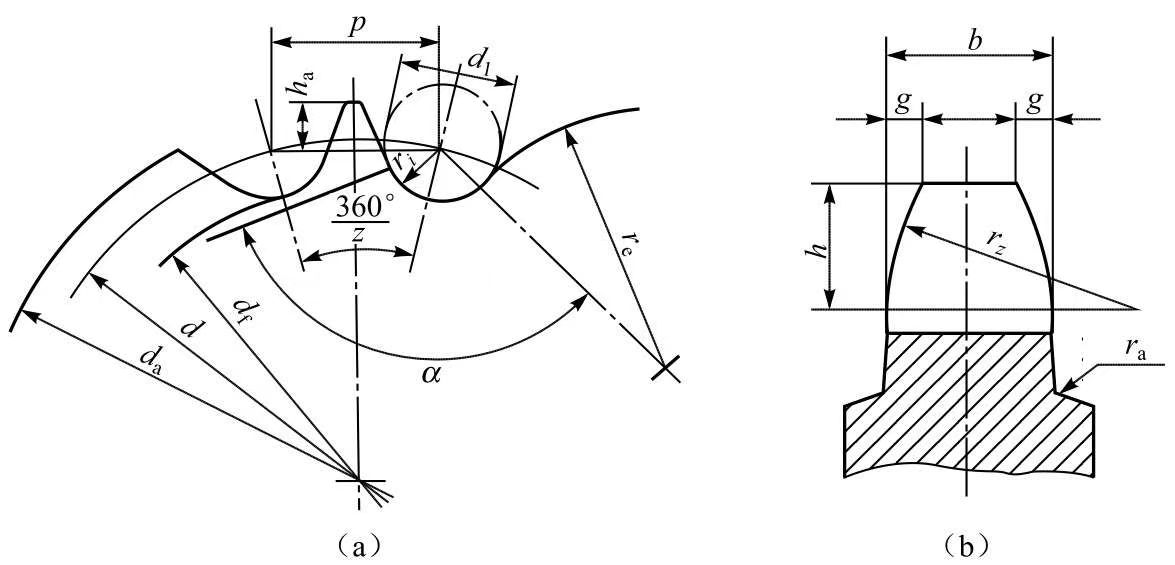

Ho utloisisa litekanyo tsa mantlha tsa li-sprocket tsa hau ho bohlokoa bakeng sa ts'ebetso e ntle ka ho fetisisa. Litekanyo tsa bohlokoa li kenyelletsa palo ea meno, bophara ba selika-likoe sa pitch, bophara ba kantle, bophara ba motso, bophahamo ba leino ka holim'a poligoni ea pitch, le bophara ba leino. Selika-likoe sa pitch ke selikalikoe seo setsi sa li-pin tsa ketane se leng ho sona, se arotsoeng ka ho lekana ke pitch ea ketane.Jwalo ka ha ho bontshitswe ka tlase:

Li-sprocket li tla ka mefuta e fapaneng ea sebopeho, ho kenyeletsoa mefuta e tiileng, e nang le masoba, e kopantsoeng le e kopantsoeng. Ho latela boholo, u ka khetha sebopeho se loketseng: li-sprocket tse nyane tse bophara li ka ba tse tiileng, li-sprocket tse bophara bo mahareng hangata li sebelisa moralo o nang le masoba, 'me li-sprocket tse kholo tse bophara hangata li kopanya thepa e fapaneng bakeng sa lesale la meno le khubu, tse hokahaneng ka ho tjheseletsa kapa ho tjheseletsa. Bakeng sa mehlala e itseng, sheba Goodwill'ssprocketlikhathalogu.

Moralo oa Leino: Pelo ea Bokgoni

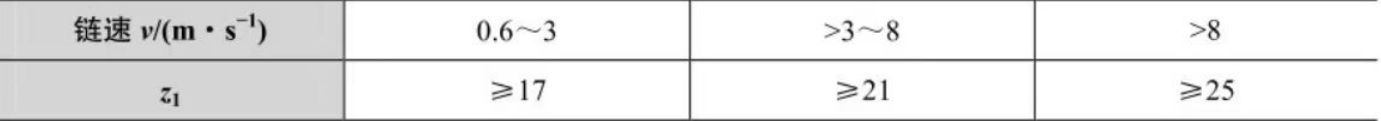

Palo ea meno holim'a sprocket e ama haholo boreledi ba phetisetso le bophelo bohle. Ho bohlokoa ho khetha palo e loketseng ea meno - eseng a mangata haholo kapa a seng makae haholo. Palo e feteletseng ea meno e ka khutsufatsa bophelo ba ketane, ha a fokolang haholo a ka lebisa ho se lekane le ho eketseha ha moroalo o matla. Ho fokotsa mathata ana, ho eletsoa ho fokotsa palo e fokolang ea meno holim'a li-sprocket tse nyane, hangata li beoa ho Zmin ≥ 9. Palo ea meno holim'a li-sprocket tse nyane (Z1) e ka khethoa ho latela lebelo la ketane, ebe palo ea meno holim'a sprocket e kholo (Z2) e ka fumanoa ho sebelisoa karolelano ea phetisetso (Z2 = iZ). Bakeng sa ho tsofala ho lekanang, meno a li-sprocket ka kakaretso e lokela ho ba palo e sa tloaelehang.

Sebopeho se setle sa Ketane Drive

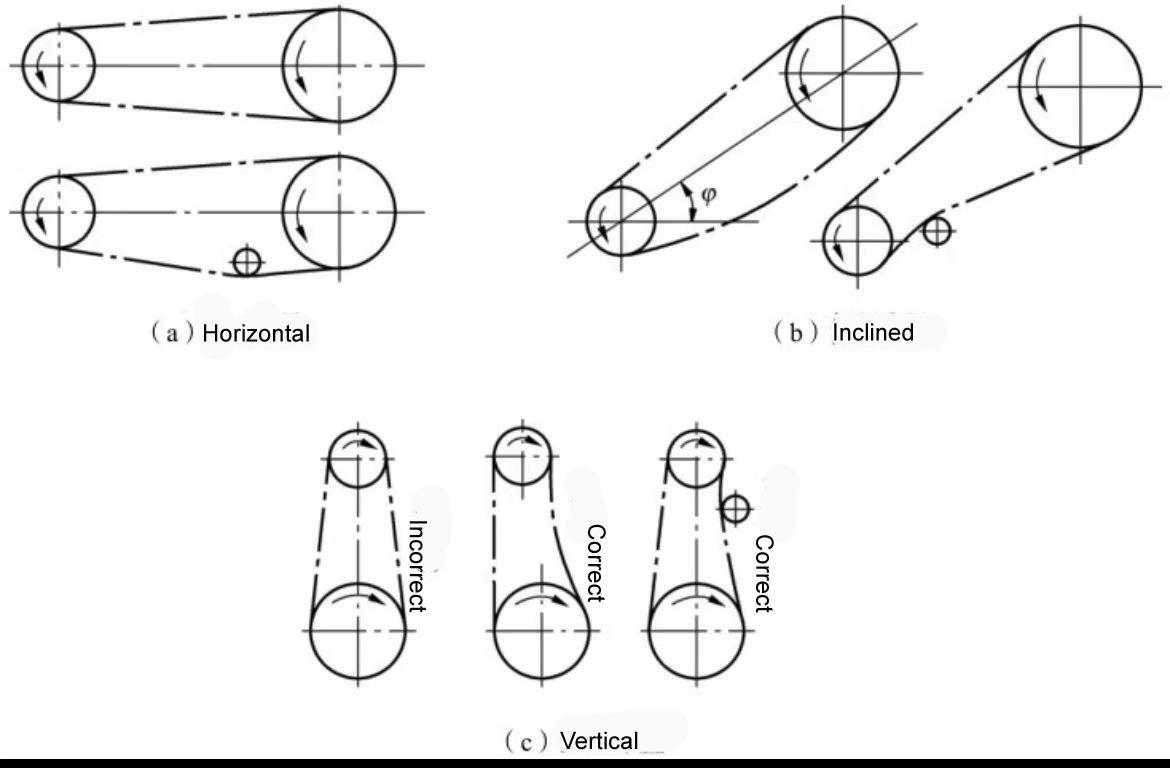

Sebopeho sa ketane ea hau ea ho khanna se bohlokoa joalo ka likarolo ka botsona. Sebopeho se tloaelehileng sa ketane ea ho khanna se bontšitsoe ka tlase.

Sebopeho se Tletseng: Netefatsa hore difofane tse potolohang tsa di-sprocket ka bobedi di lebane ka hara sefofane se le seng se otlolohileng le hore di-axe tsa tsona di bapile ho thibela ho kgaohana ha ketane le ho senyeha ho sa tlwaelehang.

Sebopeho se sekametseng: Boloka sekhutlo pakeng tsa mela e bohareng ea li-sprocket tse peli le mola o otlolohileng se le senyenyane kamoo ho ka khonehang, haholo-holo ka tlase ho 45°, ho qoba ho kopana hampe ha sprocket e ka tlase.

Sebopeho se Otlolohileng: Qoba ho ba le mela e bohareng ea li-sprocket tse peli ka sekhutlo sa 90°; ho e-na le hoo, thiba li-sprocket tse ka holimo le tse ka tlase hanyane ka lehlakoreng le leng.

Ho Beha Ketane Sebakeng se Tiileng: Beha lehlakore le tiileng la ketane holimo le lehlakore le thekeselang ka tlase ho thibela ho thella ho feteletseng, e leng se ka lebisang tšitisong ea meno a meno.

Ho Tsitsisa Tshebetso e Ntle

Ho tsitsisa ka nepo ha ketane ho bohlokoa ho thibela ho thella ho feteletseng, e leng se ka lebisang ho se kopane hantle le ho thothomela ho fokolang. Ha sekhutlo se pakeng tsa li-axes tsa li-sprocket tse peli se feta 60°, hangata ho sebelisoa sesebelisoa sa ho tsitsisa.

Ho na le mekhoa e fapaneng ea ho tiisa, 'me e tloaelehileng haholo ke ho lokisa sebaka se bohareng le ho sebelisa lisebelisoa tsa ho tiisa. Haeba sebaka se bohareng se ka fetoloa, u ka se fetola ho fihlela khatello e lakatsehang. Haeba ho se joalo, lebili la ho tiisa le ka eketsoa ho lokisa khatello. Lebili lena le lokela ho beoa haufi le lehlakore le lesesaane la sprocket e nyane, 'me bophara ba lona bo lokela ho tšoana le ba sprocket e nyane.

Bohlokoa ba ho Tlotsa

Ho tlotsa ho bohlokoa bakeng sa ts'ebetso e ntle ea li-drive tsa ketane, haholo-holo lits'ebetsong tsa lebelo le phahameng le tse boima. Ho tlotsa ho nepahetseng ho fokotsa ho tsofala haholo, ho fokotsa litlamorao, ho eketsa bokhoni ba mojaro, le ho atolosa nako ea bophelo ea ketane. Ka hona, ho bohlokoa ho khetha mokhoa o nepahetseng oa ho tlotsa le mofuta oa setlolo ho netefatsa ts'ebetso e sebetsang hantle.

Mekhoa ea ho tlotsa:

Ho tlotsa ka letsoho kamehla: Mokhoa ona o kenyelletsa ho sebelisa nkho ea oli kapa borashe ho tlotsa oli likheong tse pakeng tsa lipoleiti tsa khokahano tse ka hare le tse ka ntle lehlakoreng le otlolohileng la ketane. Ho khothalletsoa ho etsa mosebetsi ona hang ka shift. Mokhoa ona o loketse li-drive tse seng tsa bohlokoa tse nang le lebelo la ketane la v ≤ 4 m/s.

Ho tlotsa ka oli e nosetsang: Sistimi ena e na le sekoti se bonolo sa kantle, moo oli e nosetsang ka har'a likheo tse pakeng tsa lipoleiti tsa khokahano tse ka hare le tse ka ntle ka lehlakoreng le otlolohileng ka kopi ea oli le phaephe. Bakeng sa liketane tsa mola o le mong, sekhahla sa phepelo ea oli hangata ke marotholi a 5-20 ka motsotso, 'me boleng bo holimo bo sebelisoa ka lebelo le phahameng. Mokhoa ona o loketse li-drive tse nang le lebelo la ketane la v ≤ 10 m/s.

Ho tlotsa ka Bathe ea Oli: Mokhoeng ona, sekoahelo sa kantle se sa dutleng se lumella ketane ho feta ka har'a pokello ea oli e koetsoeng. Tlhokomelo e lokela ho nkoa ho qoba ho qoelisa ketane ka botebo haholo, kaha ho qoelisa ho feteletseng ho ka lebisa tahlehelong e kholo ea oli ka lebaka la ho sisinyeha 'me ho ka etsa hore oli e chese haholo le ho senyeha. Botebo ba ho qoelisa ba 6-12 mm bo khothaletsoa ka kakaretso, e leng se etsang hore mokhoa ona o lokele li-drive tse nang le lebelo la ketane la v = 6-12 m/s.

Ho tlotsa ka oli e fafatsang: Mokhoa ona o sebedisa setshelo se kwetsweng moo oli e fafatsang ka poleiti ya splash. Ebe oli e lebiswa ketane ka sesebediswa sa ho bokella oli se ka hara casing. Botebo ba ho qoelisa poleiti ya splash bo lokela ho bolokwa ho 12-15 mm, mme lebelo la poleiti ya splash le lokela ho feta 3 m/s ho netefatsa ho tlotsa ka katleho.

Ho tlotsa ka kgatello: Mokgweng ona o tswetseng pele, oli e fafatswa ketaneng ho sebediswa pompo ya oli, mme nozzle e behilwe ka bohlale sebakeng seo ketaneng e kopanang ho sona. Oli e potolohang ha e tlotse feela empa e boetse e fana ka phello ya ho phodisa. Phepelo ya oli bakeng sa nozzle ka nngwe e ka lekanyetswa ho latela bophahamo ba ketaneng le lebelo ka ho sheba dibuka tsa tataiso tse amehang, e leng se etsang hore mokgwa ona o tshwanelehe bakeng sa di-drive tse nang le matla a maholo tse nang le lebelo la ketaneng la v ≥ 8 m/s.

Ho fihlella tshebetso e ntle le bokgoni bo botle ditsamaisong tsa hao tsa metjhini, ho bohlokwa ho utlwisisa dintlha tsa bohlokwa tsa kgetho le tlhokomelo ya di-sprocket tsa ketane. O se ke wa tlohela katleho ya metjhini ya hao e le ntho e sa lebellwang—etsa diqeto tse nang le tsebo tse hlahisang diphetho tse tshwarellang!

Ho khetha thepa, litekanyo le maano a tlhokomelo a nepahetseng ke senotlolo sa ho netefatsa hore ts'ebetso ea hau e tsamaea hantle le ka katleho. Ka ho beha lintlha tsena pele, u ka ntlafatsa nako e telele le ts'epo ea lisebelisoa tsa hau.

Haeba o na le lipotso mabapi le li-sprocket kapa o hloka tataiso ea litsebi, ka kopo u se ke oa tsilatsila ho ikopanya le rona hoexport@cd-goodwill.comSehlopha sa rona se inehetseng se mona ho u thusa ka litlhoko tsohle tsa hau tsa pele!

Nako ea poso: Pulungoana-21-2024